Phosphating agents for metal surface treatment under paints / Zinc phosphates

Pragofos 1380

nitrite-based zinc phosphating process nearly maintenance-free

The Pragofos 1380 process is convenient for the phosphating of steel, galvanized as well as zinc plated steel substrates under all types of paints (solvent-based, water-based, electrophoretically deposited, powder coatings). At the process, a very fine and crystalline layer of zinc phosphate of the specific weight 1,5 – 2,5 g/m2 will be formed. The phosphate coating created is capable of a very strong paint anchoring and, hence, boosts the overall anti-corrosion performance of the paints applied.

Furthermore, the phosphating layer will impede and delay subcorroding of the paint if locally damaged to the bare substrate. The process should be used for the treatment of steel, galvanized or zinc plated steel being exposed in severe environments, such as for vehicles, agricultural machinery, household appliances etc., with high demands for corrosion durability and life. Package of the basic concentrate Pragofos 1381: 50 litres netto in PE barrels or 1000 kg netto in PE containers.

Pragofos 1500

nitrite-free zinc phosphating process nearly maintenance-free

The Pragofos 1500 process is suitable for the formation of zinc phosphate coatings without any chemical nitrite-based accelerator content. It may be used for the phosphating of steel, galvanized as well as zinc plated steel substrates. The phosphate layer created is a good anchoring base under all types of paints including powder paints. As a sole coating, it is an appropriate temporary corrosion protection of the steel parts. In case the activation process in the Pragofos 1007 bath is employed just before the phosphating, the phosphate coatings resulted are of very fine crystalline structure of the specific weight 1,5 – 6,0 g/m2. The specific weight of the phosphate coating on a machined steel substrate may reach as much as 15 g/m2, especially if pickling operation being employed just before the phosphating. The thicknes values of the phosphate coating measured, anyway, are strongly influenced by the type of the steel to de phosphated as well as its heat treatment history.Package of the basic concentrate Pragofos 1501: 50 litres netto in PE barrels or 1000 kg netto in PE containers.

Pragofos 1510

technology for nitrite-free zinc phosphating process

The Pragofos 1510 process is suitable for the creation of zinc phosphate coatings, without any nitrite-based accelerator content, on steel, galvanized steel and zinc plated steel substrates. The phosphate coating provides a good anchoring base for subsequent conservation layers as well as all types of paints including powder coatings. The agent should be applied by immersion or spraying at the temperature within 53 – 60°C, the specific weight of the coating being about 1,5 – 4,5 g/m2. Just before the phosphating, the surface activation to enable the formation of fine-grained phosphates is recommended.

The Pragofos 1511 concentrate is supplied in PE barrels of 50 litres net content while the Pragofos 1932 accelerator component in PP pails of 10 kg net weight

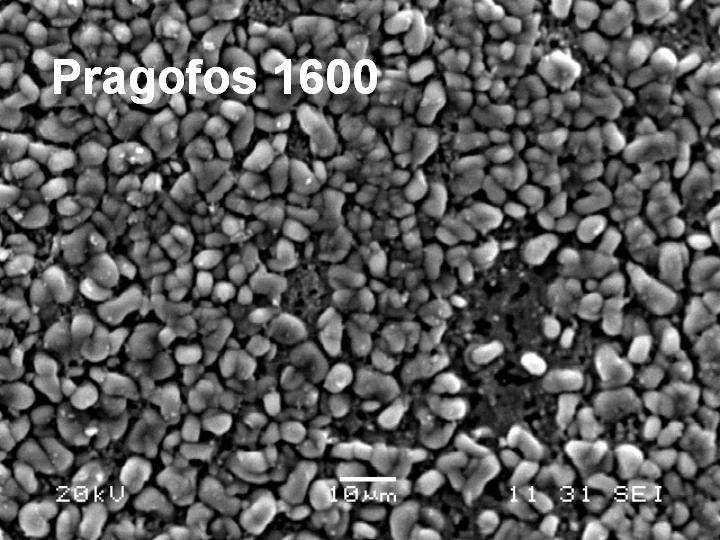

Pragofos 1600

process for the formation of zinc-and-calcium phosphate coatings

The Pragofos 1600 phosphating bath is able to form coatings of an “egg-like” structure with a good anchoring capability under powder paints and rubber (e.g. rubber silent blocks or anti-vibration mounting) which otherwise are very difficult to adhere to bare steel. Owing to the half content of the crystalline water retained, compared with other phosphates, the Pragofos 1600 phosphate coating is even able to withstand much more elevated temperatures. The bath itself will provide the coatings of a fine-grained phosphates without necessity of the activation process before. The phosphates resulted are of the specific weight within 2,5 – 4,5 g/m2. Packages of both the basic concentrates Pragofos 1601 and Pragofos 1602: 50 litres netto in PE barrels or 1000 kg netto in PE containers.

Pragofos 1900

nitrite-free process for the formation of phosphate coatings under cataphoretically deposited paints

Pragofos 1900 is an up-to-date phosphating process, without any other chemical accelerator, nickel, copper as well as alkaline nitrites, for the formation of a zinc phosphate of enhanced corrosion durability the specific weight of which varies within 2 – 4 g/m2. The bath is formulated as a multi-cationic phosphating process which is able to create the compact phosphate coatings at the self-control of the bath iron ions content. The distinctive feature of the bath is a restrained formation of the bath sludge which may be separated by sedimentation and then filtered readily. Package of the Pragofos 1901 basic concentrate: 50 litres netto in PE barrels.

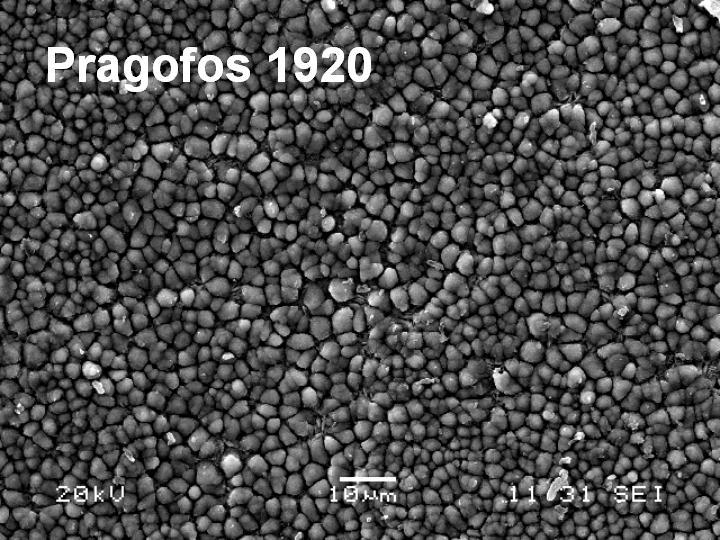

Pragofos 1920

nitrite-free multi-cation phosphating process under cataphoretically deposited paints

Pragofos 1920 is a multi-cationic phosphating process without the content of any chemical nitrite-based accelerator, which is able to create both compact and fine-grained crystalline zinc phosphate coatings of enhanced corrosion durability, the specific weight of which varies within 1,5 – 3 g/m2. The bath itself is running at the self-control of the bath iron ions content. The feature of the bath is a restrained formation of the bath sludge which may be, moreover, separated by sedimentation and then filtered readily. Package of the Pragofos 1921 basic concentrate: 50 litres netto in PE barrels.

Pragofos 1930

mixed zinc and manganese phosphate for the surface treatment before the conservation for the temporary protection

Pragofos 1930 is an up-to-date zinc and manganese phosphating agent, working without any auxiliary oxidant-based accelerator, especially suitable for the steel phopshating before its conservation. The agent deposited forms compact crystalline-based zinc and manganese phosphates of enhanced anticorrosion performance and capability to embed rather large surface concentration of the conservation agents, the specific surface weight of the phosphates deposited being within 6 – 15 g/m2. This multi-cation phosphate agent features the self-controlling ability of the ferrous ions content in the phosphating bath. The sludge resulting at the process is easy to be settled down and filtrated. The agent may be applied by both immersion and spraying techniques at the bath temperature within 48 – 55 °C.

© PRAGOCHEMA spol. s r.o. 2025