Phosphating agents for metal surface treatment under paints / Iron phosphates

Pragofos 750

combined degreasing and phosphating technology for the applications in spraying machines

The Pragofos 750 agent enables degreasing together with creation of iron phosphate conversion layer in one bath and is convenient for the hand applications by mobile pressure spraying machines (e.g. WAP, Karcher etc.) where a continuous dosing of the agent into pressure water of the temperature 60 - 100 °C is made possible. The technology is particularly suited for the treatment of large machinery parts which cannot be commonly treated by immersion or in running-through spraying lines. The dosing concentration of the agent varies within 0,2 - 2 %.

Package: 20 kg net weight in PE cannisters.

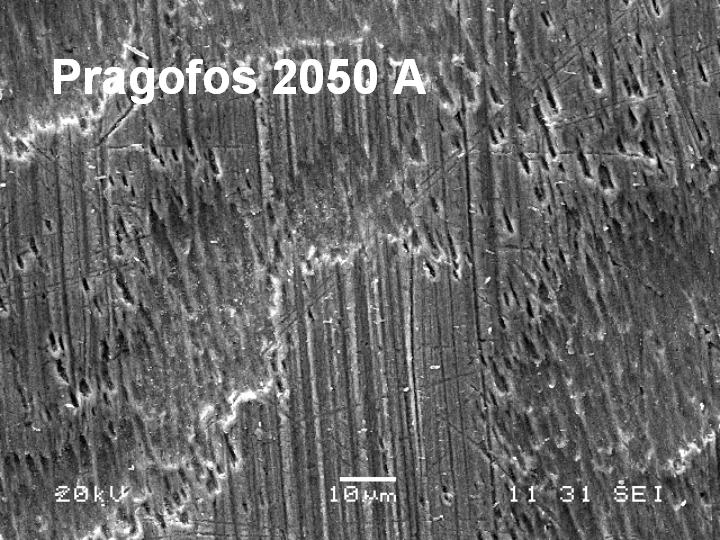

Pragofos 2050 A

combined technology for phosphating together with degreasing in one bath

Pragofos 2050 A is an agent for the formation of a very compact iron phosphate coating on steel of the specific weight 0,5 g/m2, together with the degreasing operation in one bath. It may be used either as a sole surface treatment operation (optionally with a subsequent passivation operation in diluted baths of the Pragokor O-120, Pragokor O-130 or Pragokor BP agents, if necessary) or as an adhesion base under the paints including the powder ones. The application techniques include immersion, spraying as well as compressed-air assisted spraying. The package of the basic concentrate Pragofos 2051A: 50 litres netto in PE barrels.

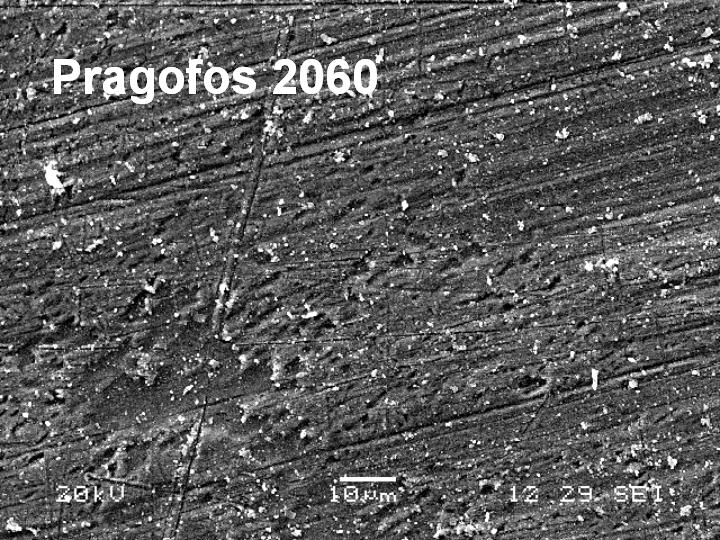

Pragofos 2060

technology for the formation of thicker phosphate coatings

The Pragofos 2060 combined process is suitable for the formation of a thick iron phosphate coating of the specific weight about 1 g/m2 on the degreased steel substrates. The steel parts are enabled to be treated together with other non-ferrous metals such as zinc, aluminium, brass etc. without deteriorating of the phosphate coating quality, the other metals present, however, not being covered with the phosphate. The Pragofos 2060 process, compared with the other similar iron phosphate baths, is capable to create two-to-three times thicker coatings the corrosion durability of which is almost up to the zinc phosphates. The Pragofos 2060 process is able to form very durable passivating layer on steel substrates as both adhesion and anti-corrosion base under all types of paints (water and solvent-based and powder paints).

The phosphating bath Pragofos 2060 A may be applied by immersion, spraying as well as compressed air-assisted spraying, the spraying and/or elevated bath temperature boosting the overall phosphating process performance.

The bath should be prepared by diluting of the basic Pragofos 2061 concentrate with water (about 3 litres of the concentrate for 100 litres of the running phosphate bath).

© PRAGOCHEMA spol. s r.o. 2025