Phosphating agents for cold-drawing processes

Pragofos 1100

technology for the deposition of a thick-layered phosphate to facilitate good adhesion of the lubricate

The Pragofos 1100 complete phosphating process is suitable for the application on the steel parts just before their cold-drawing. The phosphate coating deposited enables very good adhesion of a drawing lubricant at a substantial reduction of the drawing forces. The water solution of the Pragofos 1001 concentrate should be applied by immersion. The package of the basic Pragofos 1101 concentrate: PE barrels, netto 50 litres or PE containers, netto 1000 kg.

Pragofos 1200

technology for the deposition of a thick-layered phosphate

The Pragofos 1200 phosphating immersion process for the formation of a very thick zinc phosphate coating on steel substrates is very suitable to create the insulation layer between two sheets (e.g. transformer sheets). Besides, together with an oil-based or wax-based impregnation or under paints, the agent provides corrosion protection of steel substrates. It may be also employed alone as an agent for the running-in of steel parts or, alternatively, as a good adhesion base under the soap lubricants at cold-drawing of steel sections. The package of the components Pragofos 1201 and 1202: PE barrels 50 litres netto or PE containers 1000 kg netto. Other package can be agreed upon if requested.

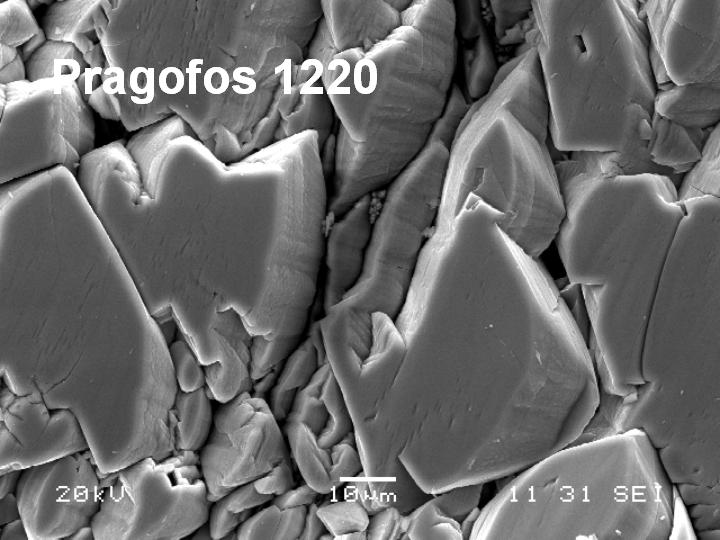

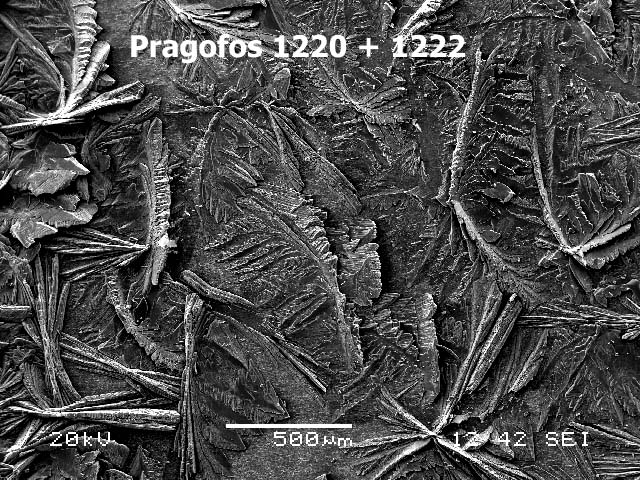

Pragofos 1220

technology for the deposition of a thick-layered phosphate at lower temperatures

Pragofos 1220 je fosfatizační proces, při kterém se vytváří povlak zinečnatého fosfátu na oceli o plošné hmotnosti 15 - 30 g/m2. Vznikají hutné, homogenní povlaky, které lze použít jako protikorozní ochranu (po impregnaci olejem apod.), jako izolaci pro trafoplechy nebo jako mazací povlak při tváření materiálu. Základní koncentrát k přípravě i údržbě lázně Pragofos 1221 se dodává v balení po 50 l (PE soudky). Jiné balení po dohodě.

Pragofos 2200

nitrites free technology for the deposition of fine-grained phosphate

The Pragofos 2200 phosphating process, without any extra chemical accelerator, is suitable for the steel treatment just before cold-forming or drawing operations and is running at varying ferric ions content which are to be removed from the bath continuously by compressed air. The bath itself, with reduced copper and nickel content, is both nitrites and organic matters free and does not contain any other substances with possible adverse affect on values of both chemical and biochemical oxygen demands (COD and BOD) in the waste water. The phosphate coatings formed from the bath are compact, crystalline, fine-grained and of the specific weight value within 6 – 11 g/m2. The other distinctive bath feature is a restrained sludge formation, the sludge being predominantly caused at the bath regeneration process by the compressed air. The sludge may be readily separated by sedimentation and filtration. The basic concentrates Pragofos 2201 and Pragofos 2202 available: 50 litres netto in PE barrels or 1000 kg netto in PE containers.

© PRAGOCHEMA spol. s r.o. 2025